In heavy-duty industrial construction, from truck trailer flooring to mezzanine systems, the connection point between timber and heavy-gauge steel is a critical engineering bottleneck. If you have ever seen wood planks lift away from a steel chassis during installation, you have witnessed the "The Jacking Action".

For B2B stakeholders, jacking is more than a nuisance; it is a drain on profitability. It forces crews to resort to pre-drilling, which doubles labor hours and increases the Total Installed Cost (TIC).

How can you eliminate the gap, skip the pre-drilling, and ensure a vibration-proof joint? The answer lies in the specialized engineering of the Wing Tip Self-Drilling Screw.

Quick Answer: What is a Wing Tip Screw?

A Wing Tip (or Wing Tek) screw is a specialized self-drilling fastener designed specifically for attaching wood to thick steel. It features two small metal wings on the shaft that ream a clearance hole in the wood. These wings snap off upon contacting the steel, allowing the threads to engage securely without separating the materials.

1. Why Ordinary Screws Fail on Wood-to-Metal?

Before discussing the solution, it is critical to understand the failure mode of standard fasteners. When a standard self-drilling screw is used on wood-to-steel applications, it creates a process-control issue known as "The Jacking Action".

- Premature Engagement: Threads grip the wood before the point penetrates the steel.

- Separation: As the screw spins against the steel, the threads force the wood upward, creating a permanent gap.

- Structural Risk: This gap creates "play" in the joint. Under dynamic loads or vibration, this leads to screw shear, fastener fatigue, and floor failure.

Operational Impact: During installation and assembly processes, such conditions may increase warranty-related costs, necessitate rework, and reduce consistency across job sites.

2. The Solution: How Self-Drilling Screws with Wings Work

The wing tip self-drilling screw is a "smart" fastener designed to automate three distinct mechanical steps into a single trigger pull.

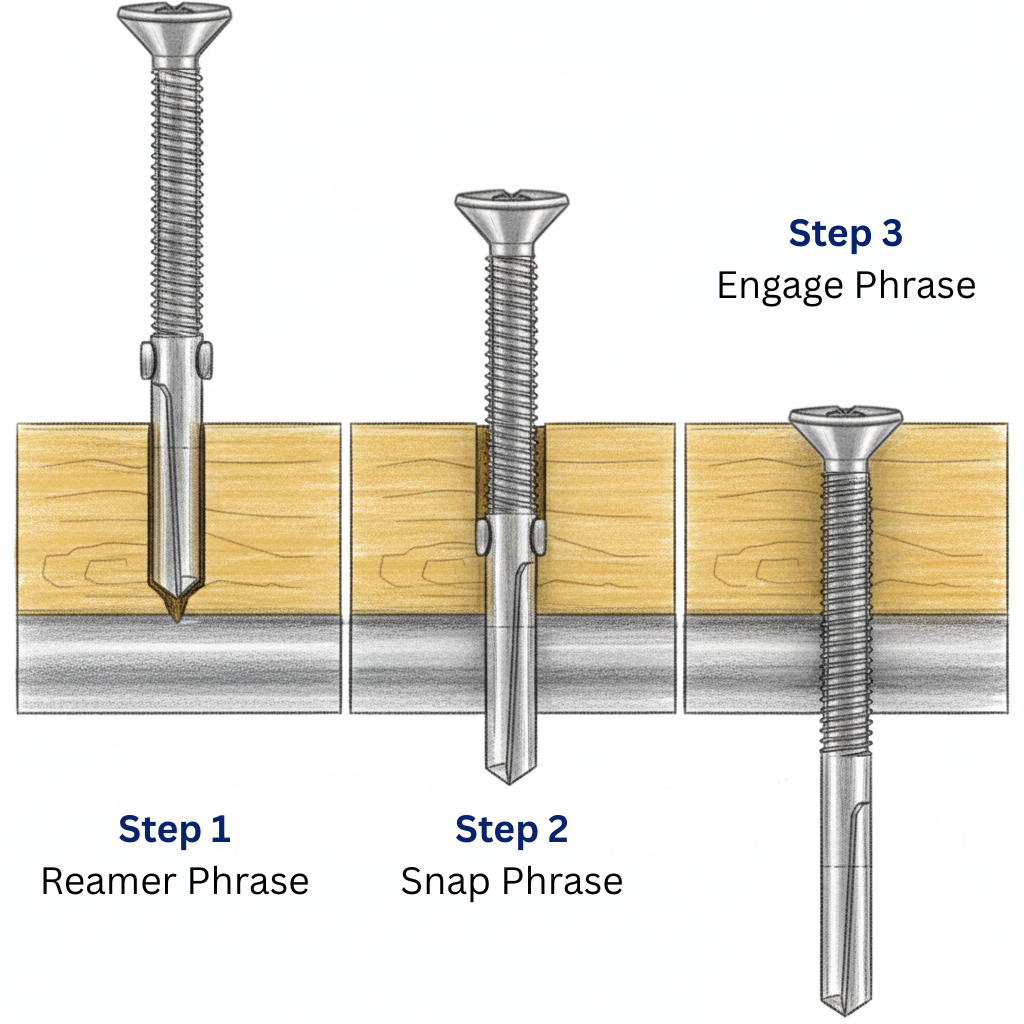

The 3-Step "Single-Drive" Mechanism

- The Reaming Phase: Two small metal wings located on the shaft above the drill point bore a hole in the wood that is slightly wider than the screw’s threads. This allows the screw to spin freely in the wood without "jacking" the plank upward.

- The Snap Phase: The wings are engineered with a specific break-off torque. As soon as the wings strike the high-density steel, they shear off cleanly.

- The Engagement Phase: Now that the clearance hole is created and the wings are gone, the drill point penetrates the steel. The threads engage the metal only when the wood is already seated flush, creating a zero-gap, high-tension bond.

3. B2B ROI: Pre-Drilling vs. Wing Tip Installation

For procurement and project managers, the value proposition is found in the labor-to-production ratio.

|

Performance Metric |

Traditional Pre-Drilling Method |

Wing Tip Technology |

|

Workflow Steps |

3 (Pilot Drill, Align, Fasten) |

1 (Direct Drive, No Predrilling) |

|

Installation Speed |

~45-60 Seconds per unit |

~10-15 Seconds per unit |

|

Joint Consistency |

High Operator Variable |

Engineered Repeatability |

|

Tooling Costs |

High (Broken drill bits) |

Minimal (Driver bits only) |

4. Technical Procurement Guide: Specifying the Correct Fastener

To ensure long-term structural integrity, fasteners must be treated as engineered components rather than commodities. When drafting RFQs, prioritize these three benchmarks to ensure your assembly can withstand the mechanical stress of heavy-gauge steel.

A high-performance benchmark for these requirements is the Countersunk Wing Tip Self-Drilling Screw with Double Thread, engineered for high-torque industrial environments:

Point Rating & Drilling Capacity: For structural steel up to 12.5mm (approx. 1/2"), a standard screw will fail. Specify an industrial-grade No. 5 wing-tip self-drilling screw. This allows for the secure attachment of 45–50mm timber to heavy beams in a single, efficient operation.

Dual-Function Thread Geometry: High-vibration environments require more than a single thread. Optimized heavy-duty wood-to-metal fasteners utilize a double-thread design: a coarse upper thread to grip wood fibers and a fine machine thread for steel engagement. This creates a "locking" effect that maintains joint integrity under dynamic loads.

Calibrated Wing Break-off & Head Geometry: Reliability depends on precision. Quality screws feature wings calibrated to withstand hardwood density but shear instantly upon steel contact. Furthermore, a specialized MS Countersunk head with under-head ribs ensures a flush, burr-free finish, eliminating the need for manual countersinking and secondary finishing.

FAQ: Common Questions About Wood-to-Metal Screws

Q1: What is the maximum steel thickness a wing tip screw can penetrate?

A1: It depends on the drill point size. A standard point #3 penetrates up to 5–6 mm. Heavy-duty screws (like a #5 point) are designed to penetrate steel plates up to 12.5 mm thick.

Q2: Why do the wings snap off?

A2: The wings are designed only to ream a clearance hole in wood. Once they hit steel, they shear off so the drill point and threads can engage the metal correctly without boring a hole too large in the steel.

Q3: Do I need to pre-drill when using these screws?

A3: No. The self-drilling feature combined with the wings eliminates the need for pilot holes in both the wood and the steel in standard conditions.

Q4: What happens if I use a standard self-drilling screw without wings on wood?

A4: You will likely experience jacking. The threads lift the wood away from the steel before penetration, creating a gap that weakens the joint and can snap the screw head.

Final Summary

Optimizing your wood-to-steel connections is about removing the variables that cause reworking. By adopting Wing Tip Self-Drilling Screws, you move from a skill-dependent process to a spec-driven process. You eliminate the jacking effect, remove the need for pre-drilling, and guarantee a high-strength joint that lasts the lifetime of the structure.

Ready to upgrade your assembly efficiency? Fong Prean provides comprehensive technical data sheets and load ratings to help you specify the exact fastener for your application.

Would you like to request a technical sample pack or a custom quote? Contact our team today.