In the world of construction and cabinetry, achieving a "flush" finish is often the difference between a professional result and a DIY failure. While a standard csk screw (countersunk head screw) is designed to sit level with the surface, the reality is that different materials, from dense tropical hardwoods to brittle fiber cement, react poorly to generic fasteners.

This is where the Fong Prean Magic Spiral (MS) design changes the game. Unlike traditional screws that rely on brute force to displace material, the patented MS head is engineered to cut its own path, providing a perfect countersink in any substrate.

The Challenge: Why One-Size-Fits-All CSK Screws Fail

Fastening into specialized panels often presents unique technical hurdles that a standard countersunk head screw cannot overcome:

- Hardwood Mushrooming: In dense woods like Oak or IPE, the material is too tough to deform, causing the wood to "mushroom" or lift around the head instead of sitting flush.

- Brittle Board Cracking: Materials such as fiber cement, MDF, and melamine are prone to "cratering" or surface chipping when subjected to the radial stress of a traditional conical head.

- PVC and Rubber Deformation: Driving an aggressive screw into PVC or Rubber boards can cause splitting or unsightly burrs that ruin the aesthetic finish.

The MS Solution: Magic Spiral Head Design for a Clean Finish

The MS countersunk head screw family transitions the seating process from "displacement" to "precision milling". By incorporating specialized geometry under the head, these screws deliver a clean, burr-free result without the need for time-consuming pre-drilling or separate countersink tools.

1. The Magic Spiral (MS) Head

Born for the "perfect countersink," this patented design features spiral grooves and cutting ribs under the flat head. As the screw enters, it carves out just enough material to seat itself perfectly flush in MDF, plywood, and laminates without leaving splinters or burrs.

2. 24-Ribs Design for High-Density Boards

For the toughest materials, such as IPE decking or fiber-cement cladding, Fong Prean offers a 24 ribs MS head. These micro-ribs act as built-in cutting edges that mill the surface rapidly, preventing the "volcano effect" common in hard materials13.

3. MS Trim Head for Discreet Aesthetics

In high-end cabinetry where the screw should "disappear," the MS Trim Head provides a smaller diameter footprint while maintaining the signature burr-free performance. It is the ideal choice for PVC wainscoting and delicate trim work.

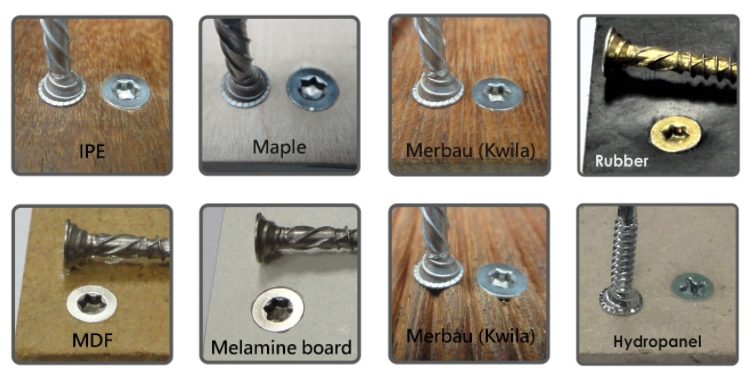

MS Series vs. Standard CSK Screws: Surface Performance Comparison

|

Surface Requirement |

Standard CSK Screw |

Fong Prean MS Series |

|

Surface Finish |

High risk of burrs, splinters, or "mushrooming" |

Perfectly Flush & Burr-Free |

|

Cleanup Time |

Requires manual sanding or deburring |

Zero Post-Installation Cleanup |

|

Material Appearance |

Likely to crack brittle surfaces or chip paint |

Preserves Material Aesthetics |

|

Fit in Pre-finished Panels |

Can ruin the finish around the hole |

Ideal for Pre-finished/Laminated Boards |

Real-World Success Across Industry Applications

1. Hardwood Decking (The MS Reamer)

Fastening expensive Merbau or IPE planks to metal frames usually requires extensive pre-drilling to prevent the wood from splitting. As a key member of the MS family, the MS Reamer ensures that dense wood fibers are cleared effectively during insertion. This allows the csk screw to seat perfectly flush without "mushrooming," resulting in a smooth, snag-free surface that is safe for bare feet and visually flawless.

2. Fiber-Cement to Metal Cladding (MS Head with Wings Tek)

The MS Head Drill Point with Wings tek screw is the MS family’s specialized solution for securing fiber-cement boards to metal studs. The integrated "wings" enlarge the pilot hole in the board to prevent stress cracking during installation, while the MS head ensures a clean, recessed seat without damaging the fragile panel surface.

3. High-End Cabinetry & PVC Panels (MS Trim Head)

For interior MDF or PVC panels, the MS trim head ensures a firm grip without bulging or delaminating the surface. This is particularly critical for pre-finished materials where there is no room for error. The MS design allows for a smooth, clean finish that can be painted or veneered over immediately with zero extra repair work or sanding required.

Conclusion: Elevate Your Projects with MS Innovation

The "one size fits all" approach to fasteners is a myth when dealing with modern, specialized materials. Whether you are an engineer prioritizing precision or a craftsman focused on high-end aesthetics, choosing the right countersunk head screw is essential to the final quality of your work.

Fong Prean’s patented MS head screw ensures that a "flush and clean" finish isn't just a goal—it’s a guarantee. By focusing on surface perfection and eliminating the common frustrations of burrs and mushrooming, the MS series family proves that the right head design makes a world of difference in the final look of your project.

Ready to upgrade your assembly quality? Eliminate secondary cleanup and achieve professional results every time. Explore our full range of MS Countersunk Head Solutions.