Product Description

Feature

Technical Patents

Instead of traditional aggressive ribs, the special 12 v-ribs and cutting teeth under head design show a perfect countersunk with clean, flush and burr-free.

Efficient Solution

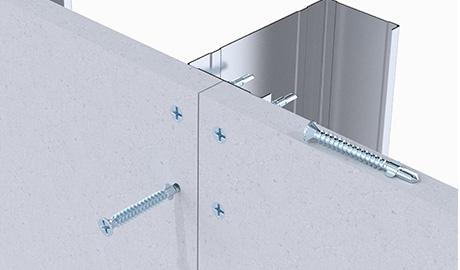

The fiber cement board incorporates a distinctive drill point equipped with wings, specifically designed for wood to steel applications, enhancing its adaptability and performance in diverse construction scenarios.

Drilling Point

Fiber Cement Board + Wood

Drilling Point with Wings

Fiber cement board + Steel (Wing tek)

Specification

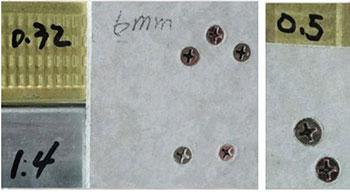

12-V-Ribs Head Fiber Cement Board Screw Showcase

To connect thickness 6mm fiber cement board to three different thickness 0.32,0.5 and 1.4mm steel plate.

With special ribs under head, it shows impressive smooth surface on fiber cement board. Clean & Flush.

Patent Fiber Cement Screw- Drill Point with Wings

A fast and efficient solution for fiber cement board installation, featuring a countersunk 12V design with wings.

This innovative design eliminates the need for pre-drilling, saving both time and effort, while ensuring a clean and burr-free surface upon installation.

FAQs

Q1: What is special about the 12-V-ribs head on these fibre cement screws?

A. The patented 12-V-ribs design under the screw head carves into the board as the head seats, allowing the fibre cement screw to sit perfectly flush and burr-free without damaging the surface. This makes it ideal for paint-grade finishes and visible applications where a smooth, clean look is essential.

Q2: Do I need to pre-drill fibre cement boards?

A. No. Our fiber cement screws are engineered to cut in and seat flush without pre-drilling. For wood-to-steel assemblies, models with a winged drill point are specifically designed to speed installation while ensuring a secure, professional finish.

Q3: What do the “wings” do, and do they break off?

A. The wings on certain fibre cement screws ream a clearance hole through the fibre cement board to prevent lifting until the screw threads engage the metal. Once the screw reaches the steel, the wings shear off, allowing the threads to cut into and clamp the metal securely. Use the “wings tek” screw option when fastening fibre cement board to metal.

Q4: Are there recommended substrate thickness ranges for these fiber cement screws?

A. Yes. These screws are tested for fastening 6 mm fibre cement boards to steel substrates of 0.32 mm, 0.5 mm, and 1.4 mm thickness. If your board or steel gauges differ, share the details with us so we can recommend the correct drill-point and wing configuration for your application.