Fiber cement boards and cement backer boards are much tougher than ordinary wood or drywall. Because of this hardness, using the wrong fasteners can lead to frustrating failures. Screws not designed for cement board may corrode from the board’s alkalinity or refuse to sit flush, causing bumps and weak spots in your installation.

The solution is simple: you need to use fiber cement screws. These are specialized fasteners made to bite into hard cementitious material and hold up over time. In this guide, we will explain what makes these screws different and how to choose the best one for your specific project.

What Are Fiber Cement Screws?

Fiber cement screws, also known as cement board screws, are purpose-built fasteners for attaching cement-based boards to framing. Fiber cement boards and cement backer boards may sound similar, but they’re not exactly the same. Fiber cement boards include cellulose fibers for added flexibility and exterior durability, while cement backer boards are denser, heavier, and mainly used as a stable underlayment for tile. Both, however, are much tougher than ordinary wood or drywall.

Unlike general-purpose screws, cement board screws come with corrosion-resistant coatings, self-countersinking heads, and high-strength steel. They often feature flat or wafer-style heads with small nibs underneath that carve into the board surface. This allows the screw head to sit flush without the need for pre-drilling or counterboring.

Importantly, fiber cement screws are made to resist the high alkalinity of cement. Quality versions are e-coated or galvanized to prevent the corrosion that would quickly destroy regular steel screws.

Why You Need Specialized Screws

Using the proper screws isn’t just a suggestion. It is crucial for a durable result.

-

Preventing Corrosion: Cement products are alkaline and can chemically corrode unprotected metal. Fiber cement screws have protective coatings to resist this alkali corrosion.

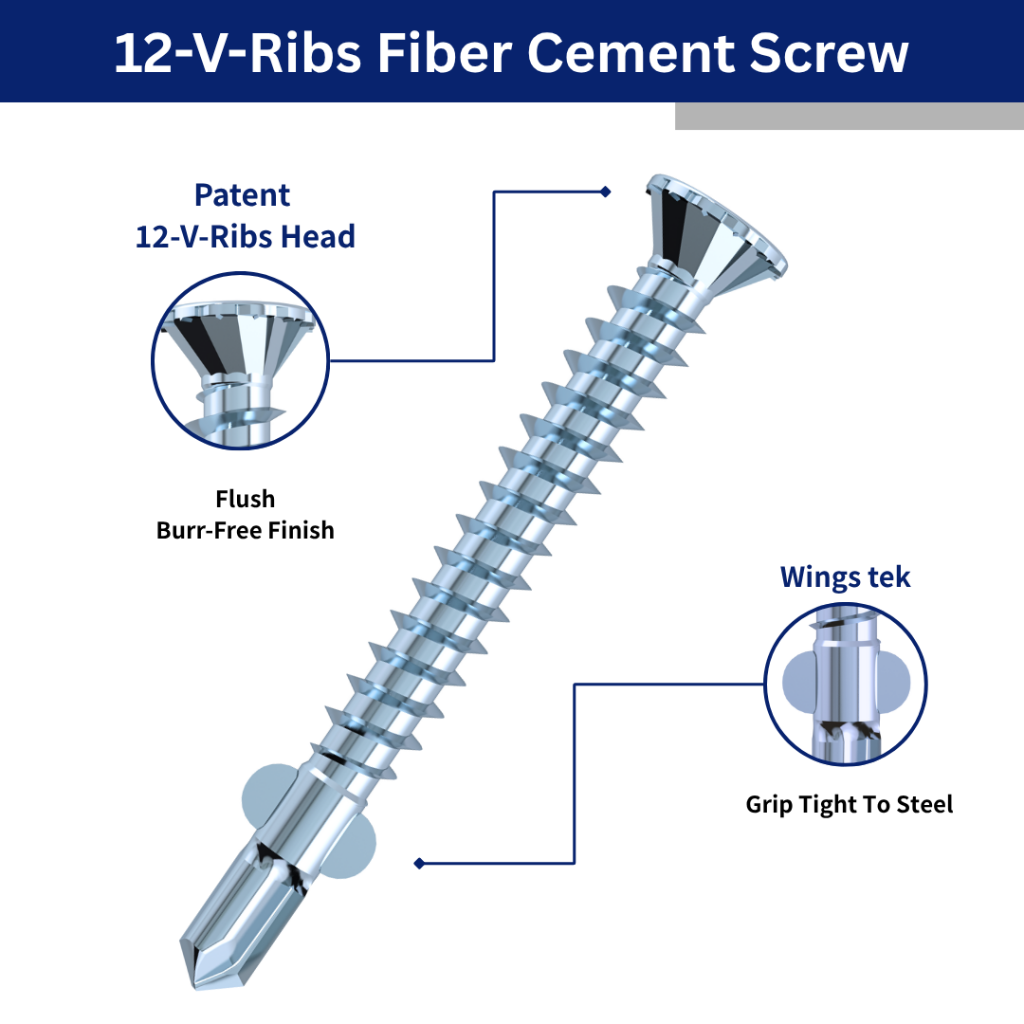

- Flush Finish: Cement board is hard and unforgiving. If a screw head doesn’t countersink properly, it will stick up. Quality cement board screws have nibs under the head that cut a clean recess so the head sits flush without tearing up the surface. For instance, Fong Prean’s patented 12-V-ribs head design includes actual cutting teeth under the head, ensuring a clean, burr-free countersink in fiber cement board.

-

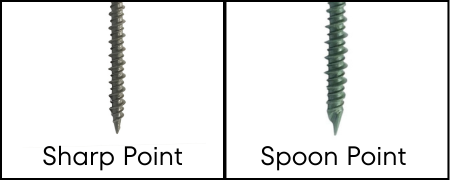

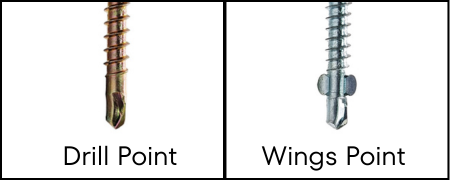

Avoiding Breakage and Wasted Time: Standard screws can snap under the high torque needed to penetrate cement board, or they may require pre-drilling each hole, which adds unnecessary time to the job. Fiber cement screws are made of hardened steel to avoid shear breakage, and many have self-drilling or wings point so you do not need to pre-drill at all. Some screws even feature a special scoop, style drill tip that carves cleanly through the board rather than dulling like standard points.

4 Key Factors When Choosing Your Screw

1. Substrate: Wood or Steel?

First, identify what you are fastening the cement board to.

-

For Wood Framing: Use screws with sharp point or spoon point. These are designed to start quickly in wood without splitting it.

-

For Steel Framing: Choose self-drilling screws. These have a small drill-bit tip, often called a TEK point, that cuts through light-gauge steel. Many also include reamer wings near the tip. These wings enlarge the hole in the cement board so it doesn't ride up the threads, then snap off when they hit the metal.

2. Length and Diameter

-

Length: As a rule of thumb, pick a screw that will penetrate at least 3/4 to 1 inch into wood framing. For standard 1/2 inch backer board on wood, 1-1/4 inch screws are the common choice. If you are going into steel studs or using thicker board, step up to 1-5/8 inches.

-

Diameter: Most cement board screws are size #8 or #9. Unless you have a specific design requiring a wider screw, stick with the manufacturer’s recommended #8 size.

3. Head Style and Drive Type

-

Head Style: Flat heads with ribs will sink flush, which is ideal for tile backer applications. Wafer heads are wider and low-profile, often used for siding where you want a larger bearing surface.

-

Drive Type: Phillips drives are common but prone to slipping. Square drive or Torx heads are highly recommended. They allow more torque with less cam-out, making your installation smoother.

4. Material and Coating

-

Coated Steel: Most screws use hardened carbon steel with a protective ceramic or alkali-resistant coating. These are suitable for indoor and most exterior jobs.

-

Stainless Steel: For exterior siding or coastal areas, stainless steel screws (grade 305 or 316) eliminate rust concerns and provide long-term performance.

Installation Tips for Success

-

Follow Spacing Guidelines: Place screws 6 to 8 inches apart along all supports. For estimating fastener quantities, refer to our Cement Board Screws FAQ.

-

Drive Flush: Each screw should be driven until the head is flush or slightly below the board surface. Avoid overdriving.

-

No Pre-Drilling Needed: With modern fiber cement screws, pre-drilling is typically unnecessary.

Conclusion

Fiber cement board installations are only as strong as the screws that hold them together. Choosing screws specifically designed for cement board ensures strength, longevity, and professional finish quality.

At Fong Prean, we understand the demands of fiber cement applications. Our screw offerings include specialized countersunk 12-V-Ribs Head screws, self-drilling TEK point screws, and reamer wing options for steel framing.

If you have any questions about selecting the right fiber cement screw, contact us anytime. And if you're comparing nails versus screws or seeking installation tips, explore our Cement Board Screws FAQ and Buying Guide for practical answers.