In the worlds of construction and structural engineering, project specifications often rely on fastener designs validated years or even decades ago. However, a 2025 improvement project involving the UFO-Frame Pro Screw highlights a frequently overlooked reality: while fasteners may remain unchanged, construction environments and materials have evolved significantly.

The UFO-Frame Pro is not a new entry to the market. For over 13 years, it has served as a reliable structural screw for steel fastening and critical support applications. For most contractors, it was a "set-and-forget" solution, a mature product that required no R&D intervention.

However, starting in 2023, consistent market feedback began to emerge: installers reported difficulty penetrating steel, inconsistent tightening, and unstable driving force. These were not isolated incidents; they were recurring issues appearing across multiple job sites. For the R&D team, this pattern was a warning signal that the status quo was no longer sufficient.

The Issue Was Not Quality, but Application Assumptions

In response to these reports, the R&D team first conducted a comprehensive quality audit. The data was clear: every screw met or exceeded original design standards. Even as penetration and thickness tests were tightened in the lab, site dissatisfaction persisted.

Reflecting on this phase, the R&D manager noted:

“If all static test data meets requirements, yet complaints continue to occur, the issue may not lie in product quality, but rather in the actual application conditions.”

This conclusion led the team to recognize a critical point: laboratory test conditions that appear “reasonable” may no longer reflect real-world job site conditions.

Testing Design Resilience Against Site Variables with Incomplete Data

Before complete application data from customers was available, the R&D team did not rush to overturn the existing design. Instead, they returned to a fundamental question: Under unavoidable construction variables, does the current design still provide sufficient stability?

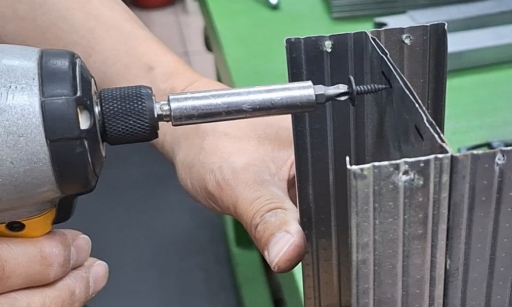

To answer this, the team adopted what they internally referred to as an “abnormal but reasonable” testing strategy, deliberately simulating scenarios most likely to amplify problems on real job sites, including:

Driving screws close to the edge of steel plates

Non-vertical driving angles and poor operator posture

Comparative testing against screws with similar drill-point designs

Initial test results showed stable performance under the originally specified material conditions. However, as required driving force increased and on-site variables were amplified, the original design’s stability began approaching the limits of its initial assumptions.

Material Evolution as the Key Factor Amplifying the Problem

As more complete customer application data became available, the R&D team shifted its focus to the building materials themselves. Analysis revealed that, driven by stricter regulations, higher structural safety standards, and increased risks from extreme weather, modern construction places greater demands on durability. As a result, the steel plates used in practice today are significantly thicker and harder than those assumed during the product’s original design phase over a decade ago.

The R&D manager explained:

“The increase in total steel plate thickness is the critical factor. As total thickness increases, the driving force required during installation also rises, which directly affects screw stability in real-world operation.”

This explains why construction variables that were previously absorbed by the original design have now become amplified. Once driving stability becomes insufficient, issues such as cam-out, slippage, or incomplete fastening are more likely to occur, increasing the risk of rework, schedule delays, and operator fatigue.

Why Not Redesign Everything from the Start?

From a market perspective, it is natural to ask: “If there is a problem, why not redesign the product entirely from the beginning?”

The R&D manager’s response was pragmatic:

“A product that has sold consistently for more than a decade must have inherent value. That value should not be dismissed lightly.”

Therefore, before obtaining the actual steel plates used by customers, the team chose to validate assumptions rather than rush into a structural redesign under incomplete information. Only after real materials were secured and test conditions closely matched actual job sites did the core issue become clearly defined: the screw required higher driving stability to meet current construction conditions. This became the true starting point for the redesign.

From a Single Case to a Repeatable Improvement Development Methodology

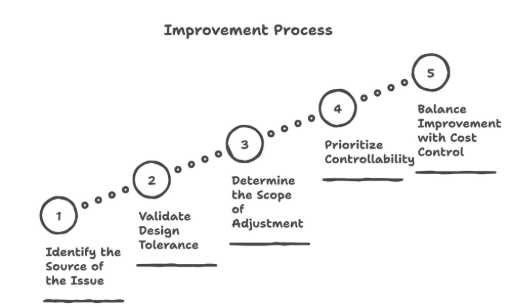

Reviewing the entire UFO-Frame Pro improvement process, the R&D team recognized that this was not merely a product optimization, but a development decision-making framework that could be replicated across all customized projects:

Identify the Source of the Issue: Distinguish between manufacturing defects and changes in application conditions using real-world data (material type, hardness, and tool condition).

Validate Design Tolerance: Use “abnormal but reasonable” scenarios (like edge fastening) to identify the true factors affecting installation stability.

Determine the Scope of Adjustment: Evaluate if the problem requires structural enhancements or minor dimensional changes, avoiding "band-aid" fixes.

Prioritize Controllability: Address cam-out and slippage during installation before pursuing performance limits or efficiency gains.

Balance Improvement with Cost Control: Use 3D design and mass calculations to improve performance without unnecessary cost increases, ensuring long-term stable supply.

This improvement development approach has since become Fong Prean’s standard R&D methodology when addressing customized projects and complex application environments.

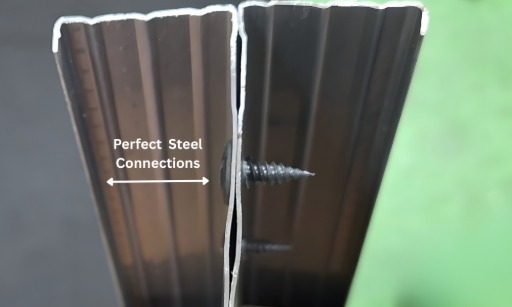

The Core of the Improvement: Stability

When redesigning the UFO-Frame Pro, the engineering logic was to improve installation stability without sacrificing efficiency or allowing costs to escalate. Through 3D design and structural calculations, the team implemented multiple key optimizations without increasing overall mass:

Enhanced drive engagement to reduce the risk of driver cam-out.

Increased chip evacuation space to allow the screw head to sit flatter against steel plates.

Introduction of an over-cutting tooth design to expand the applicable steel thickness range.

Improved performance in thin-plate applications to prevent slippage and ensure secure fastening.

Field application results showed clear improvements in installation effort, operational stability, and fastening reliability with the upgraded UFO-Frame Pro.

Conclusion: True Reliability Lies Not Only in the Product, but in the Thinking Behind It

From the user’s perspective, the most immediate benefit of the UFO-Frame Pro improvement was a reduction in “unpredictable costs” on job sites including rework risk, fatigue, and safety concerns.

More importantly, this case demonstrates Fong Prean’s consistent approach: we do not provide answers first; we seek to understand the application environment before deciding if design changes are necessary. As the R&D manager emphasized, fastener compatibility must be reviewed regularly as materials evolve.

By systematically clarifying application conditions and making disciplined design adjustments, the team transformed a challenge into a validated methodology. This approach drove approximately 33% order growth for the UFO-Frame Pro after its reintroduction, achieved not through price competition, but through a deep understanding of construction reality.

FAQ

Q1 | What key application information do we typically confirm with customers at the early stage of a project?

To ensure R&D evaluations reflect actual conditions, we recommend providing:

Actual Material Conditions: Material type, thickness, and hardness (sending a physical sample is highly recommended).

Field Context: Photos or videos of installation and failure points to help us understand site constraints.

Scope and Consistency: Confirming if the issue is site-wide or localized to avoid misjudgment.

Q2 | Under what circumstances would we recommend that redesign is not necessary?

If the issue originates from isolated installation conditions, tool settings, or incidental factors—and the product remains stable within its original design assumptions—the R&D team typically does not recommend structural modification.

Q3 | How long does it usually take from problem confirmation to proposing an improvement solution?

Generally, it takes two to four weeks from problem confirmation to initial proposals. If further validation is required, prototype samples may be produced for on-site trial installation to ensure the solution matches job site conditions.

Interviewee|Tom Huang (R&D Manager)

An experienced R&D professional specializing in product development and innovation.

In this interview, Tom shares practical insights into the thinking and challenges behind product development.