The salt spray test is a simple but powerful way to check how well a screw resists rust. At Fong Prean, we use this test as part of our inspection process to make sure our construction screws stay strong and reliable in harsh environments.

What Is a Salt Spray Test?

A salt spray test (also called a salt fog test) is a lab test that simulates how metal reacts to long-term exposure to salty air or moisture. Here’s how it works:

- Test Setup: Screws are placed in a sealed chamber with a constant temperature of about 35°C.

- Salt Mist: A solution of saltwater (usually 5% sodium chloride) is sprayed into the chamber to create a fine mist.

- Time Check: The screws stay in this mist for many hours—sometimes up to 1,000 hours or more—while being checked for signs of rust.

The goal is to see how long a screw can resist corrosion. The longer it lasts without rusting, the better its coating performs.

This test is widely used across industries, especially for metal parts used in outdoor or coastal areas. It provides a fast way to compare protective coatings and predict how well a product will hold up in real-world conditions. While it’s not a perfect simulation of natural weathering, it offers valuable insight into the durability of screw coatings.

Why Does the Salt Spray Test Matter for Screws?

Construction screws often face tough conditions, like rain, moisture, or salty air. If a screw rusts too quickly, it can weaken the structure it supports. That’s why the salt spray test is so important. It helps:

- Check Quality: Make sure each batch of screws meets rust resistance standards.

- Compare Coatings: See which coating lasts longer and gives better protection.

- Give Confidence: Help builders choose the right screw for the job.

At Fong Prean, we use salt spray tests to check the effectiveness of our screw coatings, especially for outdoor or heavy-duty use.

Common Salt Spray Test Results

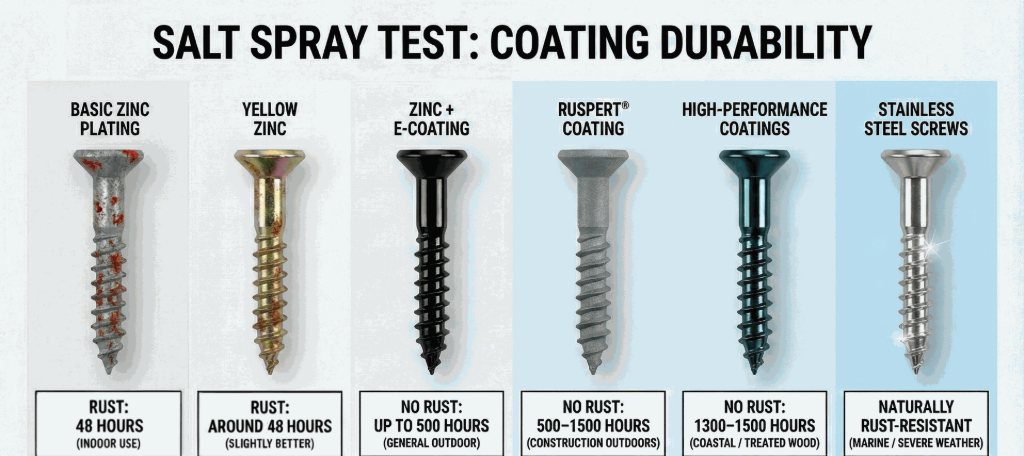

Salt spray test results are measured by how many hours a screw lasts before red rust appears. Here are typical numbers for different screw coatings:

- Basic Zinc Plating: May show rust in 48 hours. Suitable for indoor use.

- Yellow Zinc: Lasts around 48 hours. Slightly better than basic zinc.

- Zinc + E-Coating: Up to 500 hours before rust. Great for general outdoor use.

- Ruspert® Coating: 500–1500 hours of protection. Ideal for construction screws used outdoors.

- High-Performance Coatings: Some special coatings last 1300–1500 hours. Perfect for coastal or treated wood environments.

- Stainless Steel Screws: Naturally rust-resistant. Great for marine or severe weather applications.

These numbers help builders pick the right screws based on where they will be used.

It’s important to note that while higher salt spray test hours often suggest better corrosion resistance, the right choice depends on the application. For example, screws for indoor furniture don’t need the same protection as those used for decks or fences. Matching the screw to the environment ensures long-lasting performance.

Salt Spray Testing at Fong Prean

At Fong Prean, we are not a lab that runs salt spray tests as a service—we’re a screw manufacturer. But we use the salt spray test to inspect and improve our products:

- New Designs: We test new coatings to make sure they meet corrosion resistance goals.

- Quality Checks: We test sample screws from production to confirm coating quality.

- Product Improvement: If test results show weak spots, we adjust the coating process to do better.

By including salt spray testing in our workflow, we ensure our screws are ready to handle tough jobs and keep structures safe.

Applications That Need Salt Spray-Tested Screws

Some construction projects expose screws to more aggressive conditions than others. Salt spray-tested screws are a smart choice for:

- Decking and Outdoor Structures: Constant exposure to rain and UV.

- Roofing and Cladding: Wind-driven rain and humidity.

- Fencing and Garden Projects: Soil contact and changing weather.

- Coastal and Marine Buildings: Salt in the air speeds up corrosion.

- Treated Lumber Construction: Chemicals in the wood can be tough on coatings.

In all these cases, screws that have passed rigorous salt spray testing offer greater peace of mind. They help prevent early rust, reduce the need for replacements, and protect the strength of the build.

Conclusion

The salt spray test is a simple yet effective tool that helps screw manufacturers like Fong Prean deliver high-quality, rust-resistant products. Whether it’s for decking, roofing, or other construction projects, choosing screws that pass the salt spray test means better performance and longer life.

At Fong Prean, we use this test to inspect our screws and make sure every product we deliver stands strong against corrosion. It’s one more way we build trust with our customers—one screw at a time.

Looking for reliable construction screws? Contact us to learn more about our corrosion-resistant fasteners, coatings, and custom solutions for your building needs.