For roofing contractors, efficiency on the job is paramount. Every minute spent fighting a tool or a fastener is a minute lost. When securing 20-gauge metal panels to wood, crews often hit a wall, slowed by screws that "walk" on corrugated panels, and impact drivers that strain against sudden torque spikes. This leads to inconsistent results, damaged panels, and a frustratingly slow installation process.

A regional roofing partner approached us with this exact efficiency problem. Their goal was simple: find a way to fasten metal to wood faster, smoother, and with more control.

This case study details how we focused on the core mechanics of drilling and driving to engineer a superior fastener: Fong Prean Twister Metal to Wood Roofing Screw.

The Challenge: Where Installation Speed and Control Broke Down

The setting was a typical metal roofing project, but the process was anything but smooth. Crews faced persistent obstacles that directly impacted their speed and the quality of their work.

Slow Starts and Surface Damage: Screw tips would frequently slide on the painted metal surface before engaging. This "walking" not only slowed down the start of every drive but also scratched the panel's finish, requiring touch-ups.

Sudden Torque Spikes & Driver Strain: After piercing the metal, the screw threads would bite into the wood so aggressively that the driver torque would spike. This physically strained the installers, drained batteries faster, and made fine control nearly impossible.

Inconsistent Driving Results: The lack of a smooth, predictable drive meant it was difficult for installers to stop at the perfect seating depth. Screws were often over-driven or under-seated, leading to an inconsistent finish across the roof.

The primary goal became clear: we needed to re-engineer the screw's point and thread to create a seamless, controllable experience from the first contact with the metal to wood roofs substrate.

A System-Level Solution: Focusing on the Tip and Thread

We zeroed in on the two moments that mattered most: the initial penetration of the metal and the drive through the wood.

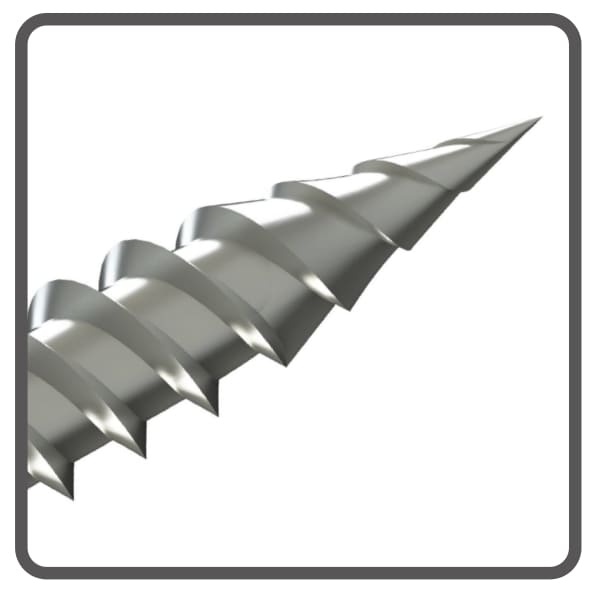

1. The "Arrowy Tip" for Instant Engagement : First, we engineered a unique, sharp point : the Arrowy Tip. Its design allows it to drill into 20-gauge steel instantly, without pre-drilling. This completely eliminates walking, allowing for faster, more accurate placement and a clean penetration every time.

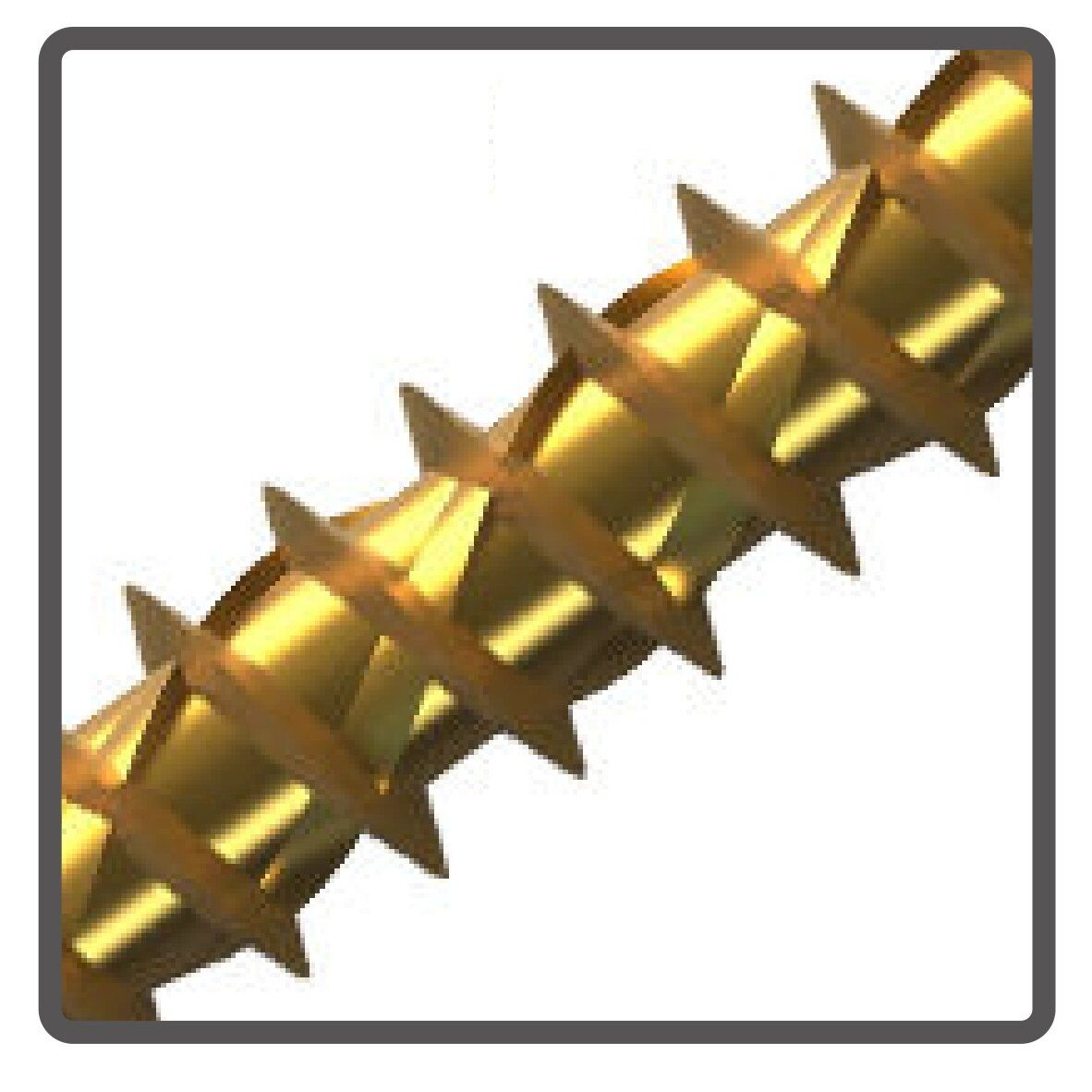

2. The Patented Low-Torque Twister™ Thread for a Smoother Drive : Next, to solve the problem of torque spikes, we developed our Patented Twister Thread. This innovative thread is designed to cut into wood with significantly less friction, resulting in a smooth, low-torque drive. This gives the installer unprecedented control, reducing wood split and allowing for precise stops at the desired depth.

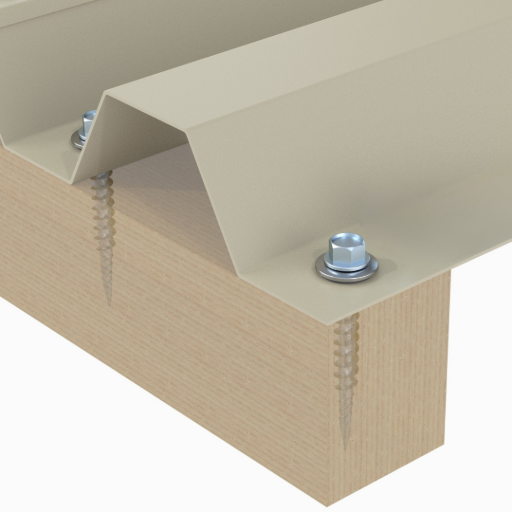

These two core innovations work together to transform the installation experience. The superior control also ensures that the screw's Hex-Washer Head and bonded EPDM washer can be seated perfectly, achieving a secure and consistent finish without the risk of over-driving.

What Changed on Roof & the Benefits

1. Faster starts on 20-ga metal

Instead of drill point, sharp tip drill into metal immediately and stays centered.

-

Less tip walking and less scuffing on corrugated panels.

Benefit: Sharp-point screws are lower cost than drill-points.

2.

Low driving torque in wood

Twister thread flattens the torque rise after breakthrough.

-

Fewer stalls; easier throttle control near seating.

Benefit: Reduced fatigue and better battery life over the day.

3. Cleaner entry, no chips

- Sharp-point design creates smaller, chip-free entry holes in metal.

- Drill-points often produce metal chips that can scratch surfaces or interfere with sealing.

Benefit: A more consistent, professional finish with fewer surface defects.

Frequently Asked Questions (FAQ)

Q1: Can a sharp-point screw really replace a drill-point on 20-gauge metal?

A1: Yes. Under typical roofing conditions and with proper installation technique, the Arrowy self-piercing point is engineered to cleanly penetrate 20-gauge steel. We always recommend you validate on your specific panel thickness and wood density before standardizing.

Q2: Does the lower driving torque mean weaker holding power in the wood?

A2: No. The Twister thread was specifically designed to reduce installation effort while its thread geometry maintains or even increases pull-out strength compared to standard threads

Q3: What benefit does a chip-free entry give when fastening 20-gauge panels?

A3: A cleaner entry with no chips means the screw head and EPDM washer land on a smooth surface. This creates a more consistent seat and a professional finish, unlike drill-points which often leave metal chips behind.

Q4: How does a sharp-point screw start faster than self-drilling screw on 20-gauge metal roofing?

A4: The self-piercing sharp-point drill into metal quickly, reducing tip walking and scuffing. This makes drilling through 20-gauge panels faster and smoother compared to drill-points.

Conclusion

Fastening 20-gauge metal roofing panels to wood purlins has always been a challenge. Drill-points slowed crews down with chips and higher costs, while traditional sharp-points risked walking and torque spikes. By focusing our development on self-piercing tip design and the low-torque Twister thread, we created a solution that delivers fast starts, smoother driving, and reliable holding power—making installation more efficient without compromise.

At Fong Prean, our mission goes beyond a single screw. Our R&D team partners with contractors, builders, and OEMs to understand real-world challenges, test solutions under jobsite conditions, and design fasteners that improve performance, safety, and productivity. From metal-to-wood roofing screws to highly specialized fasteners, every development starts with one goal: We live for solving problems.

Have a fastening challenge of your own? Connect with the Fong Prean R&D team and let’s explore how we can design a solution tailored to your application.