Introduction: The Hidden Impact of Screw Performance

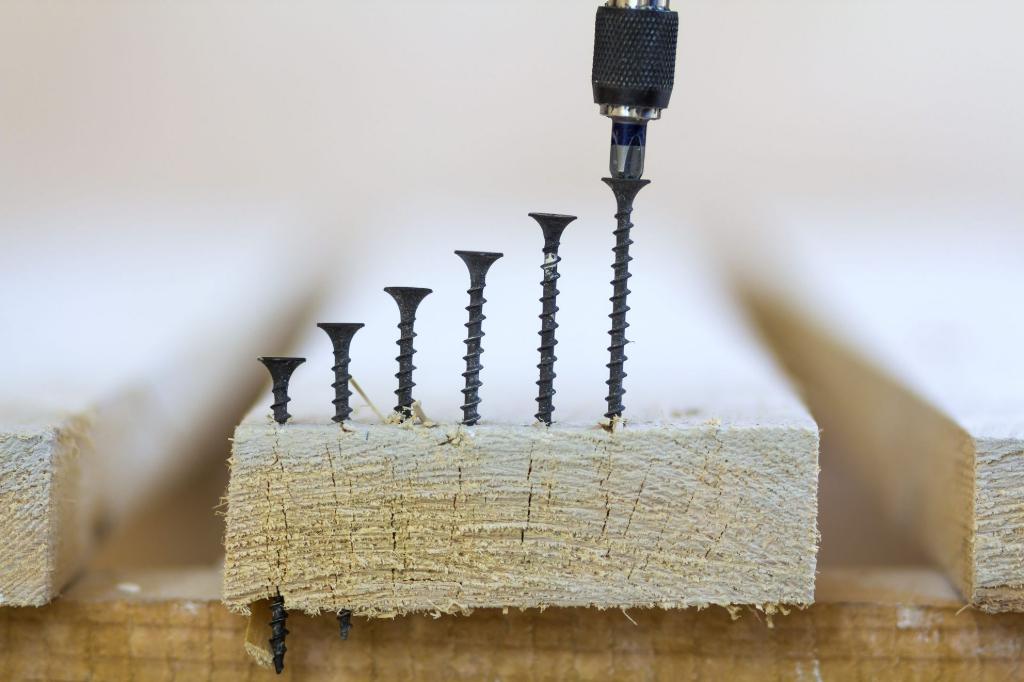

In construction and woodworking, even the smallest detail—like the type of screw you choose—can have a massive impact on project efficiency, durability, and safety. While many professionals focus on installation speed, the real breakthrough comes from fasteners that combine low driving torque with high holding power.

This balance means faster installs, reduced operator fatigue, and stronger long-term connections. Let’s break down why these two technical factors matter, and how they translate into real-world job-site advantages.

What Is Driving Torque and Why It Matters?

Driving torque refers to the force your power tool needs to drive a screw into wood, panels, or composite boards.

- Lower torque = easier installation

- Less stress on power tools = longer tool life

- Reduced operator fatigue = higher productivity on large projects

👉 In controlled lab tests on Yellow Pine, screws engineered with lower driving torque consistently delivered smoother installs compared to standard wood screws.

What Is Holding Power and Why It Matters?

Holding power describes how well a screw resists being pulled out once installed. This is especially critical because wood and other building materials expand, contract, and shift with temperature and moisture changes.

- Higher holding power = safer, long-lasting connections

- Prevents loosening in high-stress points such as doors, hangers, and fixtures

- Essential for exterior applications like decking and façades, where constant movement occurs

👉 In independent lab tests, screws with optimized thread design delivered significantly higher pull-out resistance than benchmark products.

Real-World Applications of Low Torque + High Holding Power

1. Large Surface Areas (Flooring, Wall Panels, Cladding)

- Low driving torque reduces tool load and installer fatigue on repetitive tasks.

- Higher holding power ensures connections remain tight, reducing callbacks.

2. High-Stress Points and Precision Work (Hangers, Doors, Fixtures)

- Superior holding power resists axial creep from vibration or movement.

- Low torque allows quick adjustments without damaging substrates.

3. Outdoor Projects (Deck Screws and Façades)

- Materials expand and contract with weather cycles.

- High holding power ensures structural integrity over years of service.

Engineering Benefit: Fewer Screws, Same Strength

A key advantage of high-holding-power screws is the ability to meet design pull-out targets with fewer screws.

- Lab data shows a potential 5–10% reduction in screw count (subject to engineering verification and local code compliance)

- Benefits include:

Lower material costs

Faster installation times

Reduced environmental footprint

Extended battery life for drivers

Scenarios & Test Results: Twister vs. Benchmarks

From the Lab to Your Job Site: MS Twister Screws

When it comes to turning this “low torque + high holding power” concept into real-world productivity, Fong Prean’s MS Twister wood screws are a proven choice.

- Engineered for Performance: The MS Twister screw design is centered on delivering low driving torque plus high holding power, aligning perfectly with lab test outcomes.

- Unmatched Job-Site Efficiency: As highlighted on the product page, the easy-driving nature of twister wood screws can lead to up to ~60% improved work efficiency, depending on the application.

- Anti-Splitting Wood Screws for Edge Work: MS Twister screws have demonstrated the ability to fasten as close as ~10 mm from timber edges, making them an excellent choice for trim, cladding, and other detail work where splitting is a concern.

- A Flawless Finish with a Flush Countersunk Head: The specialized MS countersunk head on twister screws sits perfectly flush with the surface while creating minimal burring, ideal for applications where appearance and precision matter.

Frequently Asked Questions (FAQ)

Q1: What does “low driving torque” mean in screws?

Driving torque is the amount of force required to drive a screw. Low torque screws are easier to install, reduce fatigue, and extend tool life.

Q2: Why is “high holding power” important?

It ensures screws stay secure under stress, preventing loosening over time, especially in outdoor or high-vibration applications.

Q3: Can using high-holding-power screws reduce screw count?

Yes, typically by 5–10%, provided designs meet engineering and code requirements.

Q4: Where should I use low-torque, high-holding-power screws?

They are ideal for large surfaces (flooring, cladding), high-stress points (fixtures, doors), and outdoor applications (decks, façades).

Q5: What’s the difference between “holding power” and “withdrawal value”?

They describe the same concept: holding power is the practical term, while withdrawal value is the technical measurement used in standards.