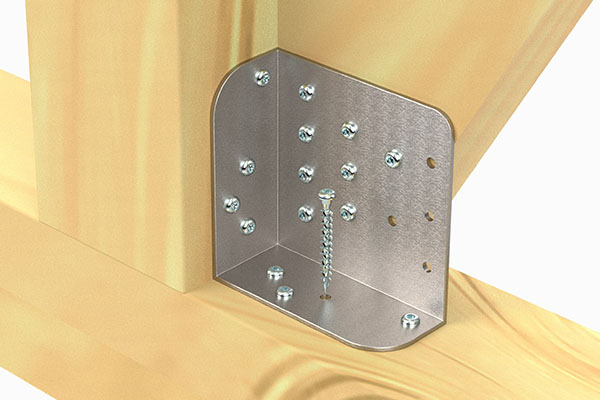

If you’ve framed a deck, set floor joists, or tightened up a roof connection, you already know the truth: the whole assembly is only as good as the connection points. Joist hangers and structural connectors look simple, but they are engineered systems and the fastener you choose is a critical part of that system.

That’s why “whatever screw is in the box” doesn’t belong here.

Many builders search for structural screws for joist hangers because they want a faster, cleaner install than hammering nails without compromising safety. That’s a good instinct. The key is knowing what makes a screw truly suitable for connector work, and how to choose the right head style for the space you’re working in.

Quick Takeaways

- Shear Strength is Priority: Standard screws cannot handle the downward force (shear) of joist hangers.

- Head Style acts as a Clamp: Neither head countersinks; both sit on top of the metal. The choice depends on clearance and bearing surface.

- The System Matters: Always verify the screw is approved for connector use and has the correct corrosion resistance for the lumber type.

What “Structural” Really Means?

Joist hangers primarily deal with shear loads that downward force from the joist, floor, or beam.

Standard wood screws (and especially drywall screws) aren’t designed for that kind of loading. Some are brittle, some snap under shock or cyclic load, and many simply aren’t tested for connector applications.

A structural joist hanger screw is different. It is built and validated for load-bearing connections, typically through controlled material, heat treatment, and geometry that supports high shear performance.

Structural screws are made to carry real loads. General screws are just made to hold things together.

Conical Pan Head vs. Low-Profile Pancake Head: It’s About Clearance & Clamping

Here is the point many buyers miss: Neither of these screws is designed to be countersunk. Because you are fastening through a metal connector hole, the head will always sit on top of the steel.

Both styles are structural and secure. The difference lies in the profile height and the clamping area.

1. Conical Pan Head: The Standard Profile

The Conical Pan Head is the most recognizable shape for connector screws. It has a slightly taller profile with vertical sides.

- The Advantage: The taller head often allows for a deeper bit recess, providing excellent grip for your impact driver.

- Best Use: General framing, open decks, and areas where you don’t have a tight layer of drywall or siding going immediately over the bracket.

See the spec: Conical Pan Head Joist Hanger Structural Screws

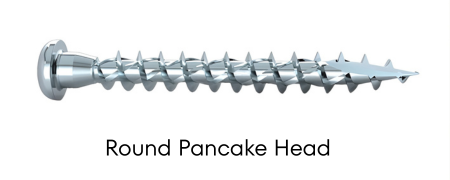

2. Round Pancake Head: The Low-Profile Option

The Round Pancake Head is flatter and wider than the Pan Head. While it still sits on top of the metal, its low profile minimizes protrusion.

- The Advantage: It offers a wider bearing surface (clamping area) against the metal connector. Because it is thinner, it creates less of a "bump" if you are installing sheathing or gypsum board directly over the hardware.

- Best Use: Tight tolerance areas where you need the fastener to be as unobtrusive as possible without compromising clamp load.

See the spec: Round Pancake Head Structural Connector Screw

The Fastener Specs That Actually Decide Success

When you’re choosing a structural connector screw, the important details are surprisingly practical.

1. Approved Use: The safest rule on any jobsite is simple: use fasteners that the connector manufacturer allows. If you are writing an RFQ or stocking for repeat builds, this is the first filter: “Is this screw intended for hanger/connector fastening?”

2. Point Style that Prevents Splitting: A lot of hanger fastening happens close to edges and ends. This is where a Type 17 cutting point earns its keep. It acts like a small drill bit, helping the screw start cleanly and reducing splitting especially in dry or dense lumber.

3. Corrosion Resistance: For decks and exterior framing, coating is not a detail it’s durability. If you are using Pressure Treated (PT) lumber or building in coastal areas, ensure your screw has a coating designed for that chemical and environmental exposure.

4. Thread Geometry: Driving a structural screw into solid timber creates friction and heat. Better thread designs (like a twisted or serrated thread) reduce driving resistance, clear dust, and keep installs consistent.

Closing Thought

Joist hangers don’t fail

because people choose “bad hardware.” They fail because fasteners get treated

like generic consumables. Once you treat the screw as part of the connector

system, confirming the fit and picking the head style that suits your clearance

needs, you end up with connections that are faster to install and easier to

trust.