Low Unit Price ≠ Low Total Cost

In construction and manufacturing projects, procurement teams often focus on the unit price of screws. It makes sense at first glance — if your project uses millions of screws, saving a few cents on each one can seem like a big win. But what if that 5% saving in material cost later adds up to 15% more in hidden project expenses?

That’s the trap of short-term cost thinking. What truly affects profitability isn’t the price per screw, it’s the Total Project Cost (TPC), or more precisely, the Total Cost of Ownership (TCO).

The right construction screw can reduce installation time, prevent rework, extend product life, and even lower maintenance costs throughout the building’s lifecycle.

As a trusted Taiwanese customized construction patent screw manufacturer serving North American and European markets, Fong Prean invites you to look beyond unit price and discover fastening solutions that make every project more efficient and more profitable.

The Hidden Cost of “Cheap” Screws

A screw that costs 5% less may end up costing a lot more overall. That’s because the real cost of a project includes much more than materials alone. It also covers:

- Installation and labor time

- Tool wear and maintenance

- Rework and warranty repairs

- Inventory and logistics management

Across the U.S. and Europe, more contractors and system builders are shifting their focus from the lowest price to total cost efficiency. The smartest choice is not the cheapest screw, it’s the one that delivers the best long-term value.

Hidden Cost Overview: What Cheap Screws Really Cost You.

|

Hidden Cost Factor | Description |

Downtime | Poor-quality screws can strip, break, or jam tools — halting production or installation. |

Labor Efficiency | A few extra seconds per screw, multiplied across thousands of installations, adds up fast. |

Rework & Repair | Loose joints or leaks require costly reinstallation and project delays. |

Warranty & Claims | Fastener failure can damage your reputation and trigger expensive warranty claims. |

Inventory & Logistics |

Managing multiple suppliers and inconsistent specs creates unnecessary administrative costs. |

These hidden costs often go unnoticed — yet they’re what truly determine your project’s profitability. Now, let’s explore how advanced screw design can address these challenges while keeping your structure secure.

Cost-Saving Pillar 1: Faster Installation & Lower Labor Costs

On-site labor remains one of the largest expenses in both U.S. and European construction. Low-quality screws that strip, jam, or break can slow down installation and increase tool wear "driving labor costs up".

High-performance screw designs, on the other hand, can make a measurable difference:

- Precision threading reduces friction and ensures smoother driving.

- Self-drilling and cutting tips eliminate the need for pre-drilling, saving time on each screw.

- Low-torque designs reduce worker fatigue and extend tool life.

For example, if each screw saves just 0.8 seconds during installation, this translates to hours of labor saved in a single workday, and significant cost reductions across an entire project.

However, many products on the market today focus solely on lowering torque and speeding up installation, often sacrificing structural holding power in the process. A screw that drives quickly but grips poorly can lead to loosening, structural shifts, or even long-term safety issues.

At Fong Prean, our design philosophy centers on balance, achieving both speed and strength. Our screws reduce driving torque and boost installation efficiency without compromising on holding power or structural integrity. This means contractors no longer have to choose between speed and safety — they can have both.

Cost-Saving Pillar 2: Preventing Rework and Warranty Claims

Even a small defect in a screw can cause big problems, from roof leaks and wall separation to corrosion damage. The cost of fixing these issues is often dozens of times higher than the screw’s original price.

Using screws with advanced corrosion-resistant coatings and stable structural design can help eliminate these risks. For example, fasteners that pass 1,000-hour salt spray tests maintain their strength and performance even under harsh weather exposure, minimizing failures during the warranty period.

Each avoided rework saves thousands of dollars in labor and delay-related costs.

Cost-Saving Pillar 3: Simplified Supply Chain and Administration

For large contractors, juggling multiple low-cost suppliers often means more paperwork, higher logistics costs, and increased risk of mismatch on-site.

Partnering with a reliable, one-stop manufacturer like Fong Prean provides clear advantages:

- Multi-application coverage: roof, flooring, and structural screws from a single trusted source.

- Streamlined purchasing: fewer orders, less inventory, and simpler logistics.

- Reliable supply: consistent quality and on-time delivery prevent project disruptions.

These invisible savings often outweigh the few cents difference in unit price.

How Custom Screw Design Reduces Total Cost

A screw’s value lies in its design details. At Fong Prean, our patent screw innovations are engineered to deliver real, measurable results on-site:

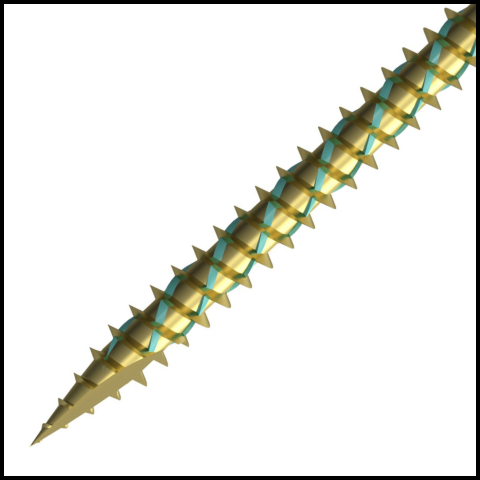

- Twister Thread / U-Cut Thread: Unique thread and cutting designs allow fast, low-torque driving without compromising structural safety, significantly shortening installation time while maintaining strong holding power.

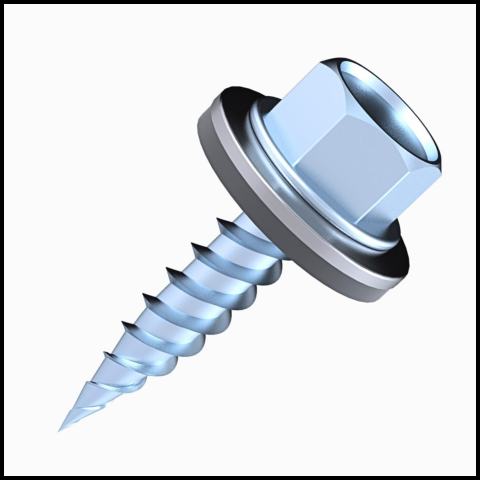

- G2 Roof Screw / CompoLock Floor Screw: Engineered for structural applications, these screws ensure watertight performance, anti-loosening strength, and long-term durability.

- Special coatings and materials: High-grade anti-corrosion coatings and stainless-steel options help minimize maintenance and replacement costs.

Together, these innovations deliver smoother installation, fewer callbacks, and longer service life, ultimately driving down total project costs.

Real-World Example: Proven Efficiency in Action

In a recent European flooring project using Fong Prean MS Reamer Screws, the contractor reported:

- No pre-drilling required; provides a clean, burr-free, flush finish for smoother installation and 20% faster assembly time

- Zero stripping or head breakage issues

- Overall project cost reduced by over 15%

In another woodworking project, switching to Twister Thread screws boosted installation speed, reduced worker fatigue, and almost eliminated product returns. These real-world results show that high-performance screws deliver value far beyond their unit price.

Long-Term Value: Quality, Durability & Sustainability

Every rework or replacement not only costs money — it adds carbon emissions and material waste. Corrosion-resistant screws extend building lifespans, reduce maintenance, and support sustainable construction and ESG goals.

In the long run, choosing high-quality screws isn’t just about cost savings, it’s an investment in durability, reliability, and brand trust.

Choose Value, Not Just Price

What drives profitability isn’t the cheapest option, it’s the smartest one. A premium-quality construction screw isn’t just a small part of your project; it’s a long-term investment that pays off in performance, safety, and total cost savings.

At Fong Prean, we work closely with our partners to understand their specific applications, from installation efficiency to product longevity and deliver fastening solutions that truly make a difference.

Let’s talk about your project needs and explore how Fong Prean’s high-performance custom screws can outperform what you’re using today.

Ling Wu, Marketing Analyst

Ling Wu is a marketing analyst at Fong Prean, focusing on market research, trend insights, and content strategy. With a passion for data-driven storytelling, Ling bridges industry knowledge with actionable insights to help businesses thrive.