What Are Low-Torque Deck Screws and Why Do You Need Them?

Low-torque deck screws are specialized fasteners engineered to reduce the rotational force (drive torque) required to install screws in dense hardwood decking materials. These screws feature innovative designs including serrated threads, self-drilling tips, and cutting flutes that minimize installation resistance by up to 35%.

Quick Answer: Best Features for Hardwood Deck Screws

- Sword and Reamer point with cutting flutes.

- Stainless steel 305/316 grade for corrosion resistance.

- Torx/Star drive recess.

- 2½"-3" length, #8-#10 gauge for standard joists.

Why Hardwood Decking Requires Specialized Screws

Hardwood decking materials like IPE (3,680 lbf Janka hardness), Cumaru (3,340-3,540 lbf), and Tigerwood (1,850 lbf) are among the densest woods used in construction. Standard screws cause these critical problems:

Common Problems with Regular Screws in Hardwood:

- Stripped screw heads from excessive torque.

- Split decking boards due to high insertion force.

- Burned-out drill motors from overwork.

- Snapped screw shafts in dense wood fibers.

- Reduced tool battery life by up to 50%.

The Solution: Low-Torque Deck Screws

Low-torque screws solve these issues using special points and designs like MS Reamer or MSowrd, which reduce resistance and installation effort while protecting your materials and tools.

Top 4 Features to Look for in Hardwood Deck Screws

1. Advanced Point Design

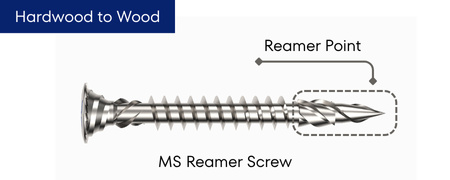

- Reamer Point: The reamer tip with precision-cutting flutes. It pre-cuts wood fibers during insertion, reducing the risk of board splitting by up to 60%. Ideal for fastening hardwood to softwood without pre-drilling.

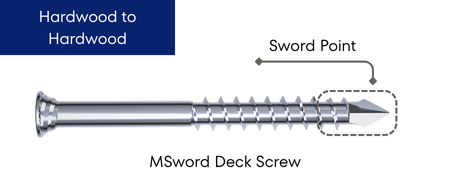

- Sword Point: Designed specifically for hardwood-to-hardwood connections, the Sword Point features a sharp, aggressive tip with optimized penetration geometry. It eliminates the need for pre-drilling.

2. Thread Technology

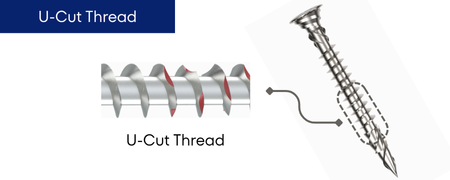

- U-Cut Threads: The thread slices through dense hardwood fibers for smoother, more efficient penetration. U-Cut geometry improves chip clearance, reduces heat buildup, and helps maintain bit alignment during high-torque applications.

3. Drive Head Options : Torx/Star Drive

- 6x less cam-out than Phillips heads

- Better torque transfer in hardwood applications

- Longer bit life in dense materials

Fong Prean Solution: Patented Hex-Star recess optimized geometry allows higher torque transfer while minimizing the risk of stripping the screw head.

4. Proper Sizing for Structural Integrity

- Length: Must penetrate joist minimum 1" (IRC requirement)

- Standard sizes: 2½", 2¾", 3" lengths

- Gauge: #8 for 5/4" boards, #10 for 2" thick decking

Cost Analysis: Low-Torque vs Standard Screws

| Factor | Standard Screws | Low-Torque Screws | Savings |

|---|---|---|---|

| Installation Time | 100% | 65% | 35% time savings |

| Tool Wear | 100% | 70% | 30% less wear |

| Split Board Replacement | 5-10% waste | 1-2% waste | $50-200 per project |

| Total Project Cost | Higher | Lower | 10-20% savings |

Note: These results are based on average data from field tests and user feedback. Actual performance and savings may vary depending on wood type, installation tools, and jobsite conditions.

Frequently Asked Questions (FAQ)

Low-torque screws use specialized thread designs, cutting tips, and flute patterns that reduce the rotational force needed for installation by 25-35%. This prevents tool burnout and wood splitting in dense hardwoods.

While possible, regular screws increase splitting risk, tool wear, and installation time. For hardwoods over 2,000 lbf Janka hardness (including tigerwood at 1,850 lbf, red oak at 1,290 lbf, and ultra-dense species like IPE and Cumaru), specialized low-torque screws are essential.

No, you do not need to pre-drill when using Fong Prean Reamer Point or Sword Point screws.

The Reamer Point screws are designed for fastening hardwood to wood without pre-drilling.

The Sword Point screws are specifically for hardwood to hardwood applications, also requiring zero pre-drilling.

Use matching metals throughout your project. If using stainless steel screws, use stainless steel joist hangers and connectors. Mixing metals accelerates corrosion.

Invest in Quality Deck Fasteners for Long-Term Success

Choosing the right low-torque deck screws for hardwood decking isn't just about immediate installation ease - it's an investment in your project's longevity. Quality deck fasteners prevent costly callbacks, reduce installation time by up to 35%, and ensure your hardwood deck maintains its structural integrity and beauty for decades.

For hardwood decking projects, prioritize Reamer & Sword point, stainless steel materials, and Torx drive heads. While the initial cost may be 20-30% higher than standard screws, the reduced installation time, lower tool wear, and decreased board waste typically result in overall project savings of 10-20%.